Using elbow pads for shoulder tire mounts. Made a bracket from 90 degree L bracket and bolted it to elbow pads. Measured and strapped with rivets to backpack harness.

Sunday, February 24, 2013

Primer parts

Primer a few parts. Started on shoulder and assembled together hood pins.

Using elbow pads for shoulder tire mounts. Made a bracket from 90 degree L bracket and bolted it to elbow pads. Measured and strapped with rivets to backpack harness.

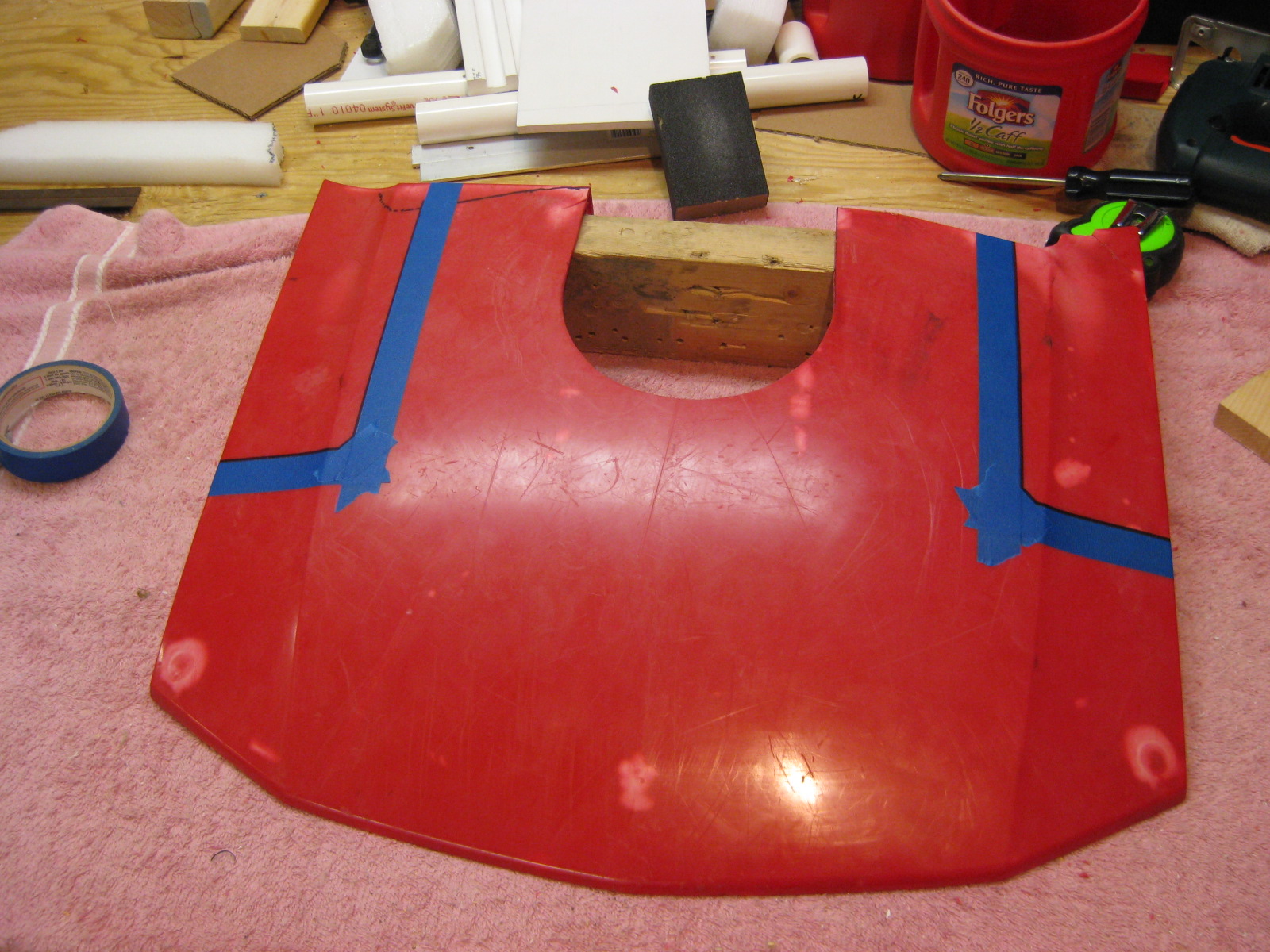

Might have to cut wheel down to a thinner size, too much mass. Weight not an issue, the wheels are hollow, just too bulky. The inside of blue tape marks is how much I will trim off.

Using elbow pads for shoulder tire mounts. Made a bracket from 90 degree L bracket and bolted it to elbow pads. Measured and strapped with rivets to backpack harness.

Monday, February 18, 2013

Modified Back Assembly

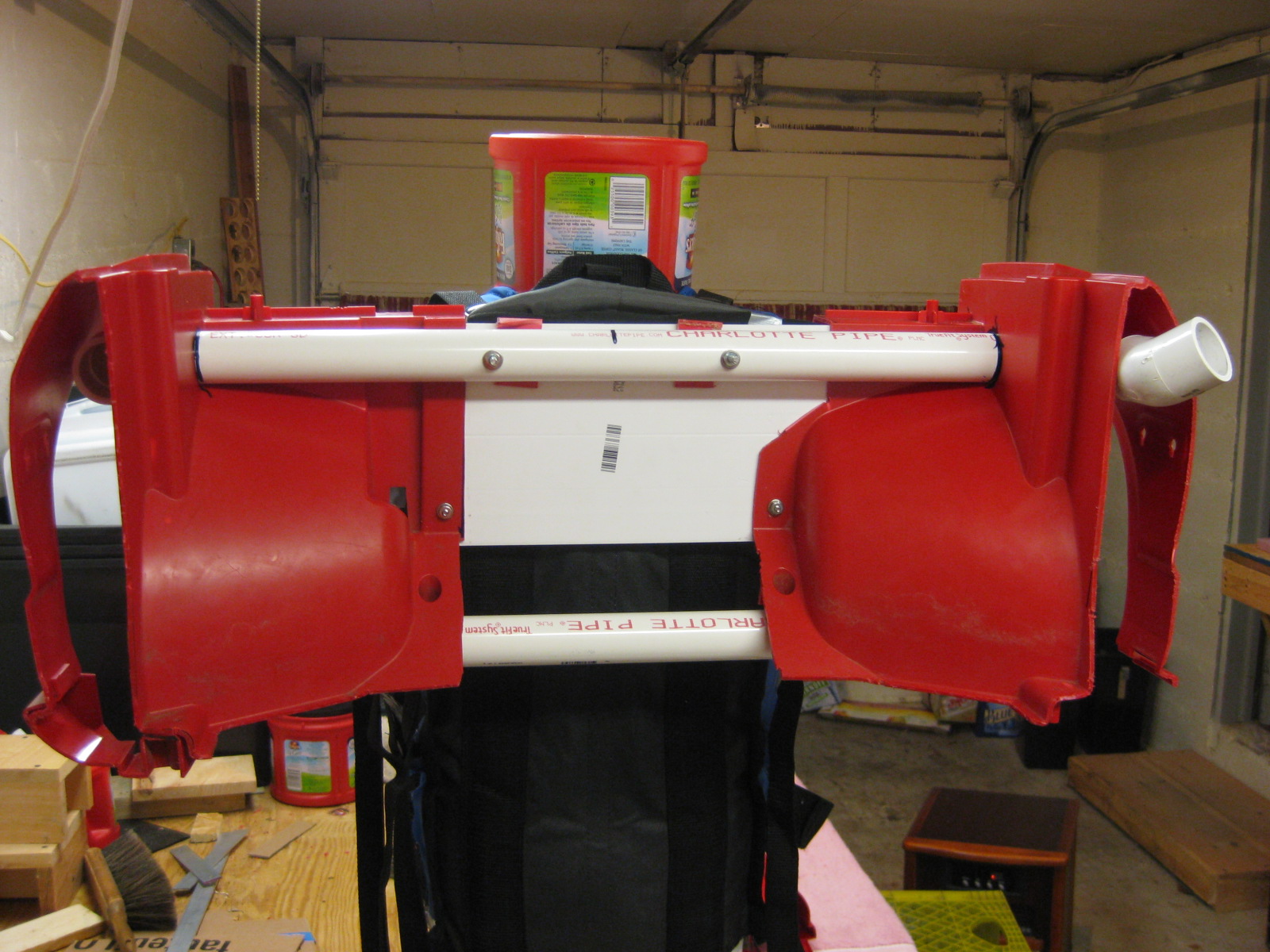

Modified the back assembly again to reduce weight and width.

Now there is room for wheels to attach onto shoulders and still have room to maneuver.

Previous back assembly restricted wheels on shoulders and had no mobility.

Received ordered plastic sheets from USPlastics.com and a new cutting tool designed for cutting plastic.

Also received more nylon straps, Velcro, elastic straps, and strap buckles.

This week will try and complete back assembly box and attach hood to shoulders or back assembly with snap buckles or adjustable Velcro straps.

Now there is room for wheels to attach onto shoulders and still have room to maneuver.

Previous back assembly restricted wheels on shoulders and had no mobility.

Received ordered plastic sheets from USPlastics.com and a new cutting tool designed for cutting plastic.

Also received more nylon straps, Velcro, elastic straps, and strap buckles.

This week will try and complete back assembly box and attach hood to shoulders or back assembly with snap buckles or adjustable Velcro straps.

Sunday, February 10, 2013

February 9th weekend

No homework this weekend so I had a lot of spare time to work on prowl project.

Found a plastic supplier online that ships acrylic sheets of solid colors both black and white in various thicknesses and sizes, at a decent price too.

Decided to reconstruct new back assembly, the original one was too wide and bulky with doors attached. I don't want to be limited going through doorways and such.

New back assembly with PVC joints for doors, inserted photo of original for comparison.

Front plates for abdomen/stomach, used two-piece rivets with 1-inch nylon strap for movement flexibility

Marked areas on hood for shoulder cut-outs.

I sometimes get second thoughts about making certain cuts that can't be undone, so I made sure the cuts on hood were what I wanted and measured correctly.

Primer grey belt sections and battery box.

I can't wait to start primer grey and painting major sections, getting tired of the red.

Inside shrouds for front grill assembly, cut the material pieces out of black plastic storage bins.

Light weight, thin and easy to cut to shape, I used cardboard templates first.

Found a plastic supplier online that ships acrylic sheets of solid colors both black and white in various thicknesses and sizes, at a decent price too.

Decided to reconstruct new back assembly, the original one was too wide and bulky with doors attached. I don't want to be limited going through doorways and such.

New back assembly with PVC joints for doors, inserted photo of original for comparison.

Front plates for abdomen/stomach, used two-piece rivets with 1-inch nylon strap for movement flexibility

Marked areas on hood for shoulder cut-outs.

I sometimes get second thoughts about making certain cuts that can't be undone, so I made sure the cuts on hood were what I wanted and measured correctly.

Primer grey belt sections and battery box.

I can't wait to start primer grey and painting major sections, getting tired of the red.

Inside shrouds for front grill assembly, cut the material pieces out of black plastic storage bins.

Light weight, thin and easy to cut to shape, I used cardboard templates first.

Wednesday, February 6, 2013

Prowl Image IDW

Just found this awesome print of Prowl and Megatron for latest IDW Transformers ongoing comic Robots is Disguise #14 cover art.

I will definitely consider modifying helmet some amount after seeing this variant of Prowl.

I will definitely consider modifying helmet some amount after seeing this variant of Prowl.

Tuesday, February 5, 2013

Helmet

Worked on helmet tonight for about 3 hours. Started getting tired when doing details around eyes. Still have another block of clay if needed. Might make helmet neck base wider. When done I will do a final finish with a wet flat trowel tool for smooth edges.

Monday, February 4, 2013

Helmet Model

Portrait of Prowl head that I will be designing my helmet after. The red forehead wing will be added later after cast is made with standard vinyl or acrylic plastic cut to fit.

This mannequin head I found in SD at an old downtown apartment rooftop. This will be used to sculpt a helmet from layers of modeling clay.

After that I will make a mold of the helmet and then create a cast helmet from the mold. I had to construct a sturdy base that allowed the head to sit level from its original crooked position.

The white helmet will be a guide for the curvature of final model helmet. Found the white helmet on craigslist.

This mannequin head I found in SD at an old downtown apartment rooftop. This will be used to sculpt a helmet from layers of modeling clay.

After that I will make a mold of the helmet and then create a cast helmet from the mold. I had to construct a sturdy base that allowed the head to sit level from its original crooked position.

The white helmet will be a guide for the curvature of final model helmet. Found the white helmet on craigslist.

Fenders on Back Harness

This past weekend allowed time to work on back section of harness. The backpack harness came with aluminum convex strips sewn into material for support. These strips are how I am attaching everything together with machine screws and other aluminum brackets.

Eventually the back section will enclose the battery bracket and have windshield/dash attach over battery. So far overall weight is approximately 10 lbs. Battery will probably add about 5 to 10 more.

One inch PVC pipe will be more than sturdy enough to support and hold back assembly together.

My initial idea for doors to attach was using aluminum one inch strips and then bent to desired angle. With PVC couplings I can get any angle I want and have a design that's able to remove doors with ease for transport and/or storage.

You can see in this photo how much the doors weight down the back assembly slightly, might have to adjust to compensate.

Eventually the back section will enclose the battery bracket and have windshield/dash attach over battery. So far overall weight is approximately 10 lbs. Battery will probably add about 5 to 10 more.

One inch PVC pipe will be more than sturdy enough to support and hold back assembly together.

My initial idea for doors to attach was using aluminum one inch strips and then bent to desired angle. With PVC couplings I can get any angle I want and have a design that's able to remove doors with ease for transport and/or storage.

You can see in this photo how much the doors weight down the back assembly slightly, might have to adjust to compensate.

Friday, February 1, 2013

WEEK 4 Jan 25th - Feb 1st

I did manage to piece together a rough idea of how the waist belt will roughly look like. I will try to have the waist belt look similar to the original toy.

WEEK 3 Jan 18th - 25th

Also applied primer paint to some plastic parts to test the bond and verify if sanding is necessary.

I will most likely do two coats of primer with sanding, and maybe just one final coat of black and white, then a final acrylic gloss clear coat.

Front end with hood temporary clamped

D-rings for attaching front grill to harness

Subscribe to:

Posts (Atom)